What is fuel flow control all about?

The dispensing of fuel from a nozzle into a vehicle’s tank should operate at the industry standard flow rate. Slower or faster fuel flow on any hose has negative implications for the site and its customers. Our smart PULSE dispenser will actively manage each hose to meet 38 lpm and is a solution that will optimise any forecourt fuel infrastructure.

Why should we even worry about flow?

Flow rates affect the quality of the customer experience. A flow rate set too low is irritatingly slow, set it too fast and we can see splash back and the nozzle clicking off repeatedly. Achieving the balance between these two extremes isn’t easy because of the dynamic environment of the forecourt, the number of hoses in use and the state of the fuel filters.

Is fuel flow control a business beneficial innovation?

The key benefits of great flow control are in creating happy, content customers, that will return knowing the fueling experience is always a consistent one. Automating flow control management to a set target flow will also optimise the life of your fuel filters.

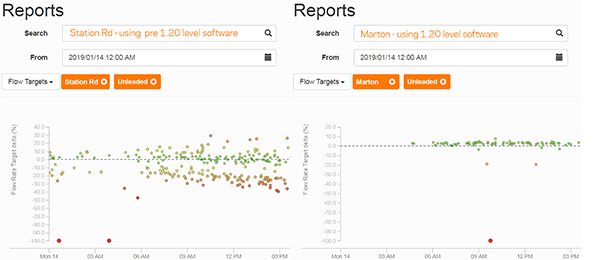

Fig 1: Gallagher Data Centre can easily show graphs with a dot for every delivery in a period. These target flow graphs show green-amber-red dots, where red is furthest from the target flow. The left-hand side, ‘Station Rd’ site does not have flow rate control and the right-hand side ‘Marton’ site has flow control activated.

Are fuel filters the only way to fix inconsistent flows, traditionally Yes!

On many sites, the only tool available to improve flow rates is to change the filters. This ‘try it and see’ approach can mean the unnecessary replacement of perfectly good filters at considerable expense for no return. In other cases, we might go to the effort of manually setting the flow rate for each hose. While this can improve the situation today, it cannot anticipate what the site fuel supply conditions might be like tomorrow.

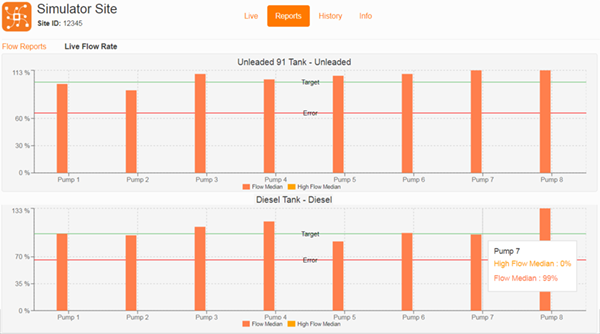

Fig 2: Gallagher Data Centre can show live median flow rates compared to the target flow for all hoses from each tank. These live values show the current performance of both hoses, for the same grade at any dispenser. It is very easy to see a single or dual grade hose inconsistency to the target flow.

How can flow control be automated?

What we really need is a system with an optimum flow rate target setting, that is continually modifying itself to achieve this target. That is exactly what the smart PULSE dispenser now does. The pump does the work for us, and when it can no longer achieve its flow targets, it alerts us to the fact that the filters may need replacing. Fewer service calls, optimizing filter life, and always providing the very best customer experience by delivering consistency – what a smart pump.

How simple is to get PULSE flow control activated?

Just ask your service agent. Update to 1.20 level dispenser software or if already at that level, just turn on flow control.

For more information on Gallagher dispensing products: https://fuelsystems.gallagher.com/